3D printing is a disruptive new technology that is impacting multiple industries. 3D printing is transforming the way we design and create objects. A few years ago, 3D printing revolutionised the medical industry when scientists reported they could print implantable human body parts.

3D printing has also had a massive effect on the architecture industry. Architecture is a competitive industry, which has embraced 3D printing with open arms. 3D printing technology allows for increased performance and innovation – benefiting architecture workflows.

So, how will 3d printing affect architecture?

Keep reading to find out more about the impact and application of 3D printing technology in the architecture industry.

What Is 3D Printing?

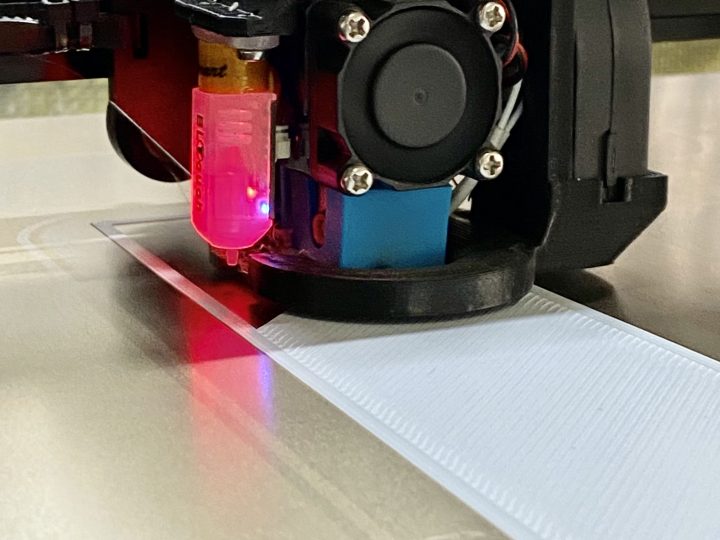

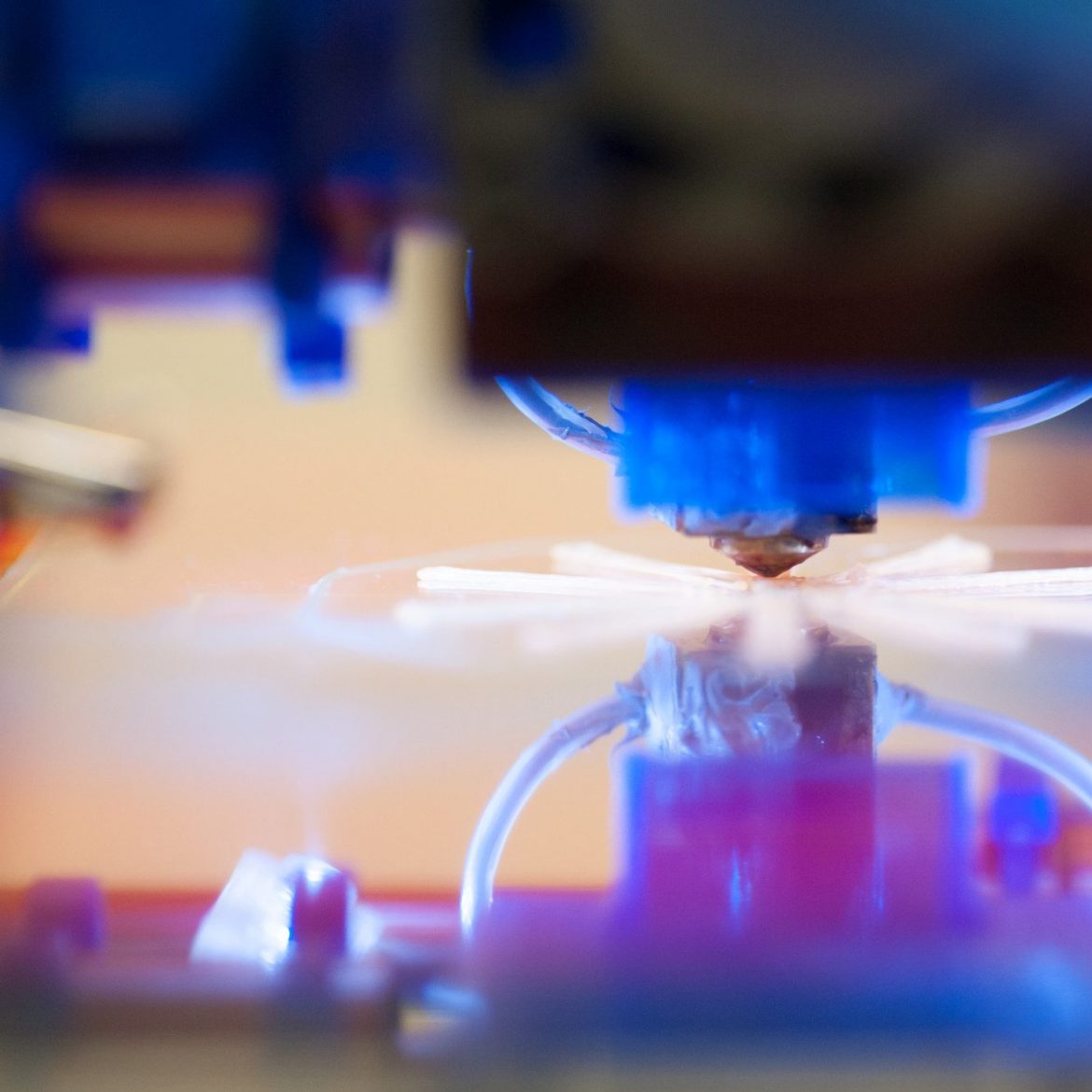

The technical term for 3D printing is ‘additive manufacturing’. It is a production technique for building solid objects from a digital file.

The file is uploaded to the 3D printer where it is analysed and read. The printer then begins to lay down successive layers of materials, until the entire design has been created.

While regular printers use ink, 3D printers use raw materials such as plastic, or resin. Architects use 3D printers to create models of a structural design, and other non-structural elements such as decorative components.

Full-scale constructions have also adopted the use of 3D printers. In 2016, Dubai showcased the first-ever 3D printed office building. Since then, a number of other full-scale projects have been completed using 3D printers.

3D Printing In the Architecture Industry

3D printing technology offers a number of benefits to the architecture industry. From improving productivity to decreasing costs, here are some of the ways that 3D printing is impacting architecture.

Faster and Cheaper Model Making

Architects create 3D scale models of projects they’re designing. Doing this by hand using foam and cardboard is a long and tedious process that can sometimes take months.

Architects can now use 3D printers to build these models instead. The process is faster and easier. 3D printers can create models in only a matter of hours. 3D printers are fast, efficient, and, unlike humans, can work nonstop through the night.

Automating the model creation process frees up time for architects to work on other, more important things.

Easier Workflow

3D printers today can be acquired at a reasonable cost and the software used for creating designs is much more user friendly. This opens up the doors for more firms to use 3D printers as part of their workflow.

3D printing technology automates a lot of the work that architects and designers would normally do manually. This alters the normal workflow, leading to increased efficiency.

All that the 3D printer requires is a digital file containing the design and the raw material. After that, the machine will do the rest. This means architects will be doing most of their work digitally instead of handling physical materials.

Dynamic Designs

3D printers can create objects with shapes and forms of high complexity at no extra cost. Using 3D printers, it’s easy to create intricate designs that would be very difficult to recreate with other tools.

As long as the design meets the printer’s specifications and the correct materials are available, there’s no limit to what can be 3D printed. This opens up opportunities for architects to be creative in their designs and push the boundaries of what’s possible.

Increased Productivity

With 3D printing technology, it’s faster and easier to produce architectural models. Printers can create multiple copies, and changes can be made at short notice. This means quicker turnaround times and increased productivity.

This is also the case with printed structures. The rate at which structures can be built and assembled using a 3D printer is lightning fast. This results in more work over time and therefore increased revenue.

Streamlines Construction

3D printing technology is providing the groundwork for a fully automated construction process. With the development of artificial intelligence and robotics, automation is the future of the industry.

Developments in 3D printing will allow projects to be completed much faster. Construction crews would enjoy better safety, less physically intense work, and improved efficiency.

3D printing also allows for better control of resources, ensuring less wastage.

The Future of 3D Printing In the Architecture Industry

3D printing provides many benefits to the architecture industry. Due to reduced cost and better efficiency, the use of 3D printing in architectural workflows and real constructions is only going to increase.

Aerospace company, Relativity Space, has even begun 3D printing rockets. In the future, we’re likely to see many new buildings and structures built using 3D printers, although this technology is still in its infancy.

Large 3D printers work the same way as regular ones. They are capable of printing entire buildings and large-scale structures. Many of the current 3D-printed structures are only concept pieces.

Regular construction requires the use of many different materials and building techniques. Current 3D printers struggle to emulate this level of precision. However, pioneers in the field are working to overcome these limitations.

It’s only a matter of time before 3D printers become the standard for construction.

3D Printing Is Disrupting Architecture

There’s no question that 3D printing is having a positive impact on the architecture industry. 3D printers reduce costs and increase productivity. They also allow for more creative and innovative designs.

Not only that – 3D printers have gotten cheaper and more user-friendly over time. Because of this, more architecture firms are adopting them for use on big projects.

Although 3D printing cannot be used in commercial construction just yet, the future of 3D printing definitely lies in the creation of large-scale buildings and objects (like rockets and aeroplanes).

These are just some of the ways that 3D printing has impacted the architecture industry. Are you looking for a 3D printing service in Melbourne? We offer a full 3D design service. Click here to get a quote.