Are you looking to introduce a new product idea? Do you want potential investors to capture the concept in a more effective way? 3D CAD printing may be exactly what you need.

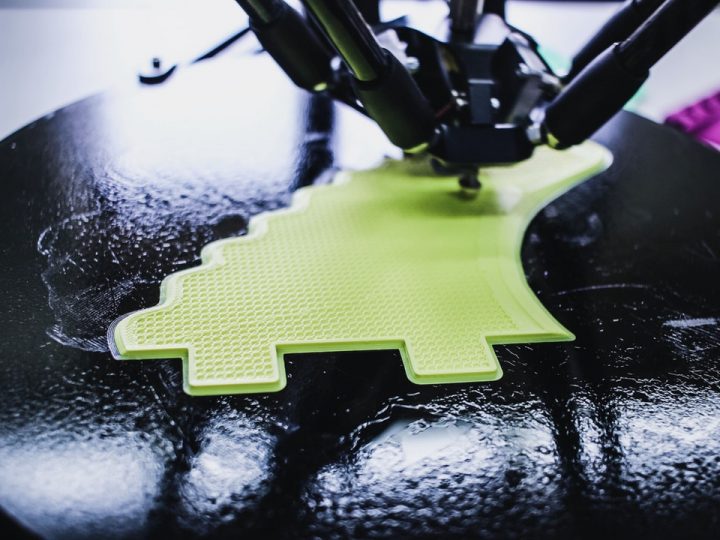

3D printing or additive manufacturing involves the production of objects using layers. These layers correspond to specific and successive 3D model cross-sections. The manufacturer adds materials like metal alloys and plastic to create shapes.

Computer-aided design or CAD pertains to designing an object with specialized software. 3D CAD and 3D printing are making waves in Australian industries.

Though 3D printing sounds like a promising option, you must first understand what it’s all about. Continue reading below as we give you the lowdown on 3D CAD printing.

The 3D Modeling Software

One of the key elements in 3D CAD printing is the 3D modelling program. In this case, it is the CAD software for 3D printing that you need.

You will use the software to create a 3D model to turn into a physical product later on. 3D CAD replaces the old-school manner of drafting a design. Instead of using the traditional pen and paper approach, 3D CAD uses an automated process.

Through the CAD program for 3D printing, you can take a 2D drawing and “pull” them out of the page, so to speak. From there, you have a 3D object staring at your computer screen. Since it’s 3D, the software lets you create designs featuring a limitless range of complex shapes.

What you can render using a 3D CAD program is a virtual reality object. As for its qualities, you can have the object feature all the properties of a real object. In turn, you will have a visual representation of a product and how it may behave in the real world.

When it comes to finding an appropriate 3D design tool, you have a lot to choose from. Here at 3D Printing Shop, we offer extensive directories of 3D model design. Find the right CAD software to suit your 3D printing needs.

3D CAD Printing Needs a 3D Printer

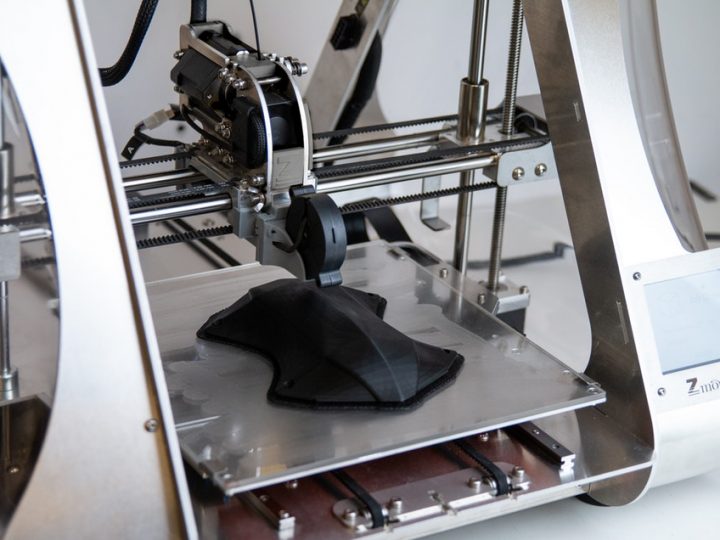

As the name of the process implies, 3D CAD printing requires a 3D printer. When it comes to the printer, there are many options available. Each type of printer caters to specific 3D printing requirements.

For example, large-production 3D printers work best for jobs with demanding requirements. These include projects that need large builds and custom parts.

For detailed but smaller projects, there are 3D desktop printers. These printers are perfect for making models, prototypes, and product designs. This type of printer is what you need in an office setup.

Meanwhile, companies that work on metal parts need metal 3D printers. There are 3D metal printers that can accommodate 3D printing requirements for mass production. On the flip side, you will also find metal printers for smaller requirements, like in the office.

Another important aspect to discuss concerning 3D printers is the materials they accommodate. As we mentioned earlier, 3D CAD printing uses different materials that you add to the layers. The most common of which include plastic and metal alloys.

However, 3D printers can also accommodate glass, acrylic, and nylon. You can also use silver, wax, polycarbonate, and stereolithography materials.

Of course, we cannot talk about printers without touching on their cost. The professional-grade can cost $10,000. As for industrial printers, they can go anywhere between $20,000 and $1,000,000.

You’re in luck as you can find a reputable 3D CAD print service that will save you a lot of money.

The 3D Printing Process

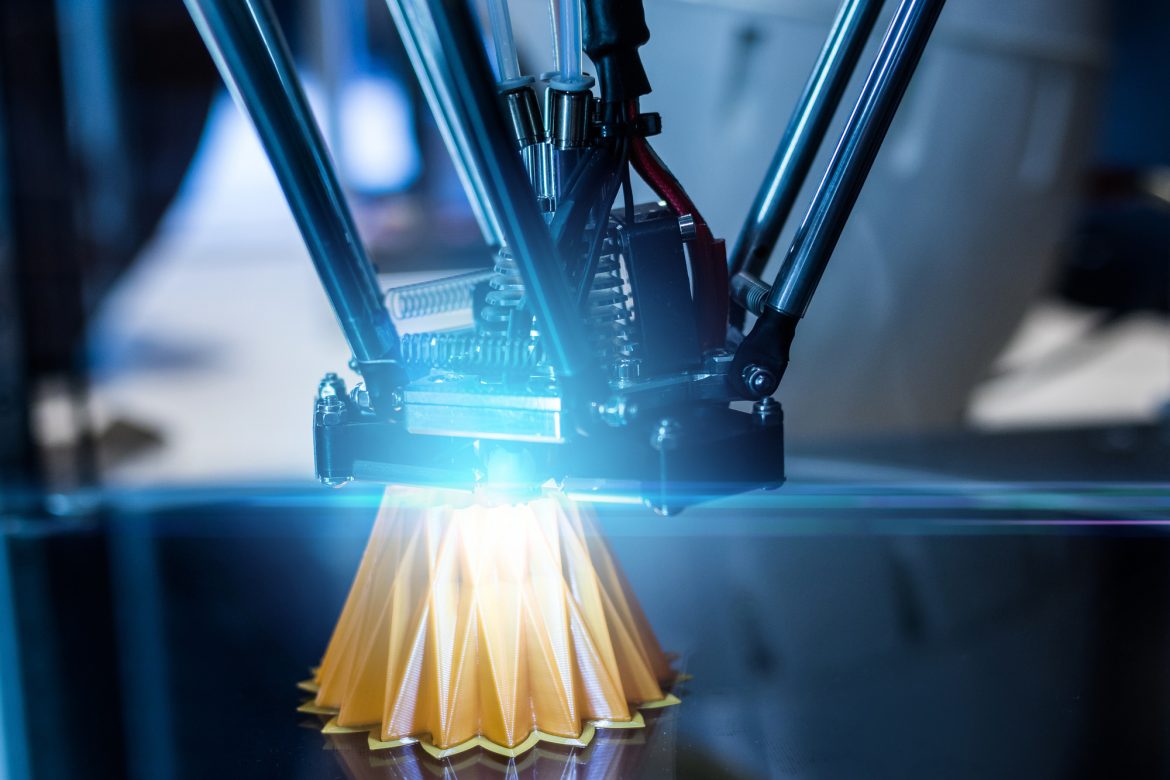

Let us now try to break down the 3D printing process. Everything starts with the creation of a digital design. Here, you will use the 3D CAD program or 3D scanner.

If you choose to use a scanner, you will scan a particular object to transfer in a 3D modelling program. Thereafter, you will convert the design into a digital file. You need to convert it to a standard tessellation language or STL format.

This is the specific format that runs on 3D printers. Next, you want to transfer the STL file to the computer that connects with your 3D printer. After transferring the file, you can apply the adjustments in size and orientation.

Next, you can start preparing for a new print job. Make sure you follow the requirements for the particular printer you’re using. Some printers require adding certain additives to print the objects.

To appreciate the building process, you need to understand the nature of each layer. The key element that affects the final product is the thickness of each layer, which is 0.1mm.

Though this may seem inconsequential, there are hundreds of layers you need to fill. Thus, you can print an object in a matter of hours to several days, depending on its size.

After 3D printing, you can remove the object from the printer. You want to avoid making contact with any hot surfaces or toxins. Apply the finishing touches by washing the object or brushing off residue.

The Different Applications of CAD Printing

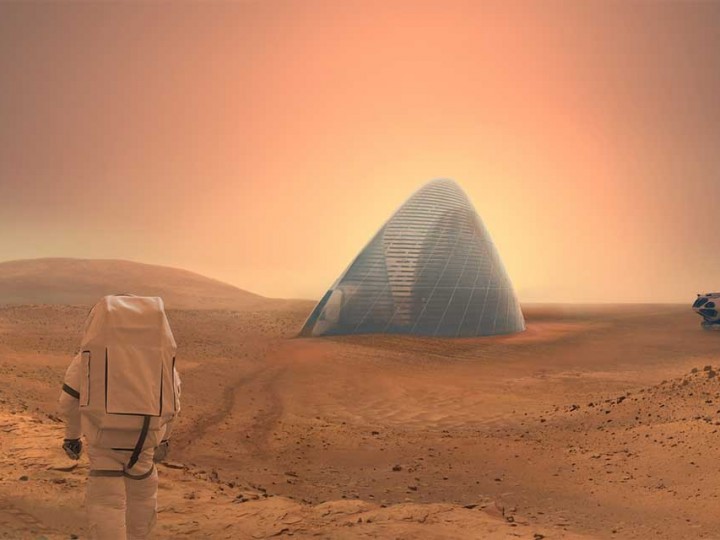

Last but not least, let us discuss the different applications of 3D CAD printing. Aside from prototypes, you can also use 3D printing to create medical models and devices.

Since the pandemic, more companies are using 3D printing to create medical solutions. Medical institutions also use it to create prosthetic limbs and organs.

Meanwhile, some non-profits also use 3D printing to create houses for the homeless. A company named Relativity Space believes they can use this to build working rockets.

Let Us Simplify 3D CAD Printing for You

Through 3D CAD printing, you can create more convincing presentations to the most discerning clients. You can better translate your ideas with more accuracy and foster more collaborations. If this is your first dip at 3D printing, we can guide you every step of the way.

Looking for 3D CAD printing in Melbourne? Connect with us today and let us know about your 3D printing targets. Request an instant quote, and let us simplify the process for you.