Even though 3D printing was just invented a few years ago, it is already exploding at an incredible rate. Just by 2020, the 3D printing market had already reached almost $14 billion. it is now expected to grow at a rate of over 20% every year!

The world of 3D printing has been used in the medical field since the very beginning. There are so many medical applications that 3D printing may soon become one of the most common tools used in the industry. But how is it being used already?

Read on to learn all about how 3D printing is improving the world of medicine!

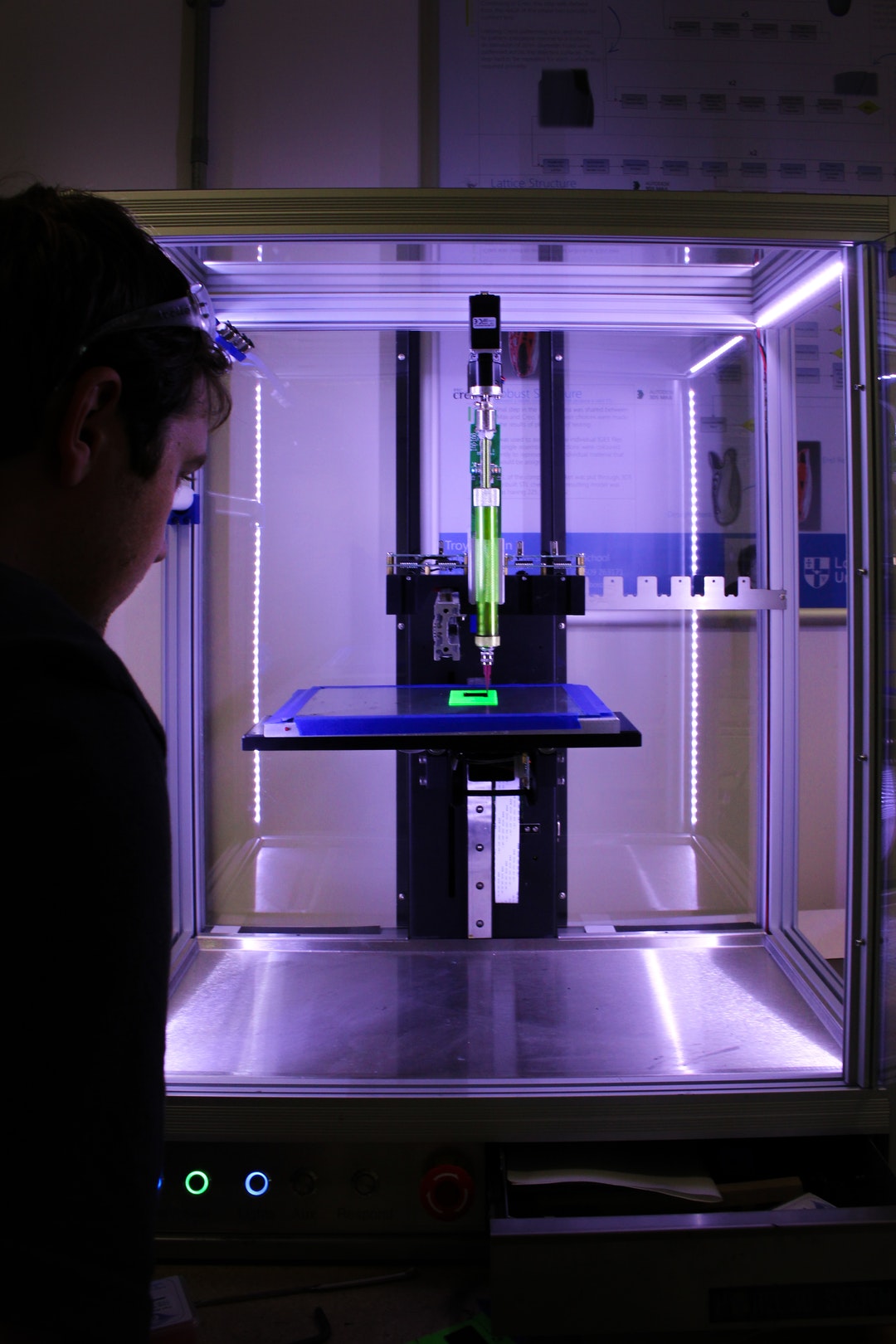

3D Printed Chemicals

When most people imagine 3D printing, they think of objects that you can hold in your hand. But this technology has advanced and crossed an incredible threshold. 3D printing can now even create chemicals, a technology with an almost unlimited number of medical applications

Right now, labs that engage in medical research are ultimately limited by the speed of transportation. They need certain tools and chemicals so that they can experiment on them and learn their properties and applications for medicine.

You can imagine how it might slow down a lab if they are waiting for trucks to transport a chemical created in China across the whole planet. What if they could just create that chemical themselves right in the laboratory?

This is what 3D printing can do for labs all around the world. Instead of having separate locations where labs synthesise chemicals and other locations where scientists study them, both things can now be done in the same place.

As soon as a single lab has discovered something new about a chemical, every lab in the world can synthesise that chemical if they so choose. 3D printing of chemicals is one of the most exciting and new ways that 3D printing is changing the medical industry.

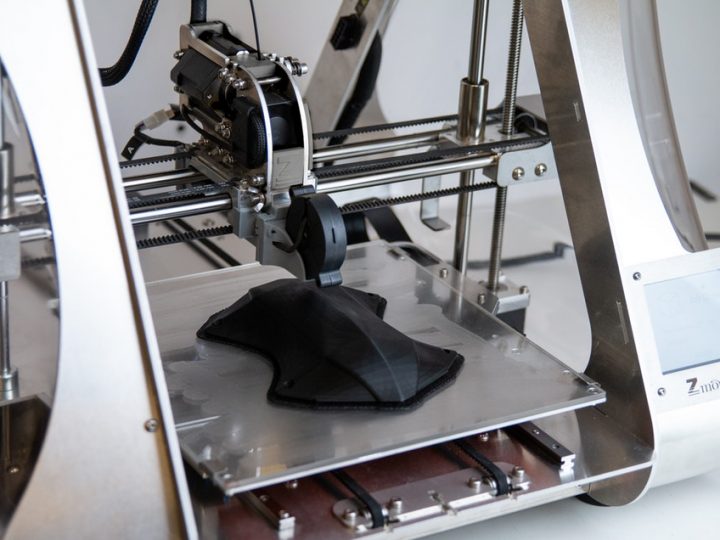

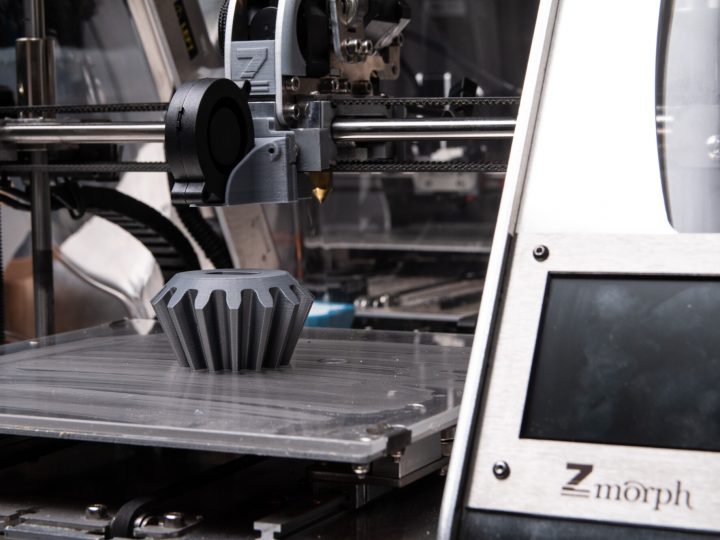

3D Printed Lab Equipment

Just like 3D printing can allow labs to create their own chemicals, it can also allow them to create their own equipment. Many medical laboratories have extremely sensitive equipment. On top of that, many experiments exert incredible forces and stresses.

Under these conditions, it is no surprise that medical lab equipment is so prone to breaking. Just as with chemicals, it can greatly slow down medical research if a lab has to ship a tool all across the world.

Not only does 3D printing of tools speed up medical research, but it also decreases costs. Many old-fashioned manufacturing techniques create products that cost hundreds of dollars. Now those same products can be created for just a few pennies of plastic!

This has many downstream results. Instead of spending money on chemicals and equipment, labs will be able to spend their money on other aspects of research.

3D Printed Inserts for Petri Dishes

One very simple way that a 3D service can help labs is by creating gel moulds for Petri dishes.

Petri dishes often have unusual requirements. For example, a lab might want to split a dish into 11 different sections, all of different sizes. It is very unlikely that a manufacturer will be already creating moulds of this exact type.

On the other hand, it can allow laboratory scientists to create a custom mould on the spot. Instead of ordering them bold from across the world, they can have one within just an hour or so.

3D Printed Bones

Just recently, scientists have used the 3D printer to create artificial bones. Not only that but these bones have actually been used as implants in real-life patients!

As usual, 3D printing allows for a customized production process. Obviously, everybody has bones of different sizes and shapes. No company in the world is creating premade bone implants in sufficient variety to cover the incredible variety of humans.

However, this printing means that they don’t have to. Each hospital or lab can have its own 3D printer.

When a patient needs a certain bone replacement, the old bone can be measured with exactitude. Then a 3D printing company can create a replacement bone of the exact specifications required.

This same technology can be used to create replacement body parts as large as whole limbs!

3D Printed Ligaments

The knees are one of the most common body parts to wear out in the human body. However, it is not actually the bones of the knee that are breaking down. Rather it is the ligaments and tendons.

It might surprise you to find out that 3D printing can even be used to create artificial ligaments and tendons. Just as with bones, 3D printing allows users to create customized products that are exact replacements for each patient’s needs.

3D Printed Medical Field Robots

Medical robots are slowly becoming a more common part of the world of medical treatment. Especially in surgery, they can move with a precision unmatched by the human hand. However, many people are concerned that they are unnerving.

Not only is this unpleasant, but some theorise that it can psychologically affect patients. There is a reason that patients appreciate doctors for their bedside manner.

3D printing tools are being developed to create softer, more appealing medical robots. These may be able to help surgeons perform their tasks without unnerving patients.

Understand How 3D Printing Is Changing the World of Medicine

We hope that you learn something hopeful about 3D printing and how it is advancing technology in medicine. 3D printing is changing not only the medical industry but almost every aspect of our lives. It will soon become one of the most commonly used tools to create everything that people need.

Follow this link to get in touch with us or to learn more about the world of 3D printing.