3D printing has the potential to revolutionize a variety of industries.

During the coronavirus pandemic, we saw the devastating impact of supply chain shortages and an overwhelmed healthcare system. In the midst of these tumultuous times, 3D printing was utilized in facilities all over the world to help generate much-needed PPE (personal protective equipment).

But 3D printing’s usefulness goes way beyond just one industry.

Are you interested in learning more about 3D printing? If so, then keep on reading and we will walk you through what 3D printing is and how it works.

What Is 3D Printing?

To put it simply, 3D printers use computer-aided design (CAD) to generate 3-dimensional items from a variety of resources, such as powders or molten plastic. While they may not be the magical devices that you see in science fiction movies, they are incredibly useful tools that utilize layering methods to create desired items.

In fact, 3D printers are not too dissimilar from standard 2D inkjet printers.

3D printers make 3D solid objects from digital files. These objects are made by applying additive processes. In an additive process, an item is created by laying down several layers of material until the item is completed.

Every single layer can be viewed as a thinly sliced cross-section of the item.

3D printing can be seen as the opposite of subtractive manufacturing, which involves hollowing/cutting out a piece of plastic or metal with a machine.

With 3D printing, you can generate complex shapes while using fewer resources than traditional methods of manufacturing.

These devices can print all kinds of objects. You can use plastics with a 3D printer to create rigid items, such as glasses.

You can also use plastic powder and make flexible objects, like bike handles or phone cases. With some 3D printers, you’ll even have the ability to use metallic powders and carbon fiber. This will allow you to make very strong industrial objects.

How Do 3D Printers Work?

As we’ve already alluded to, 3D printing is a kind of additive manufacturing and it uses similar methods to standard inkjet printers.

3D printers utilize a combination of precision tools, powder-like resources, and high-quality software to make a 3D item from scratch.

Let’s go over some of the main steps that 3D printers follow below.

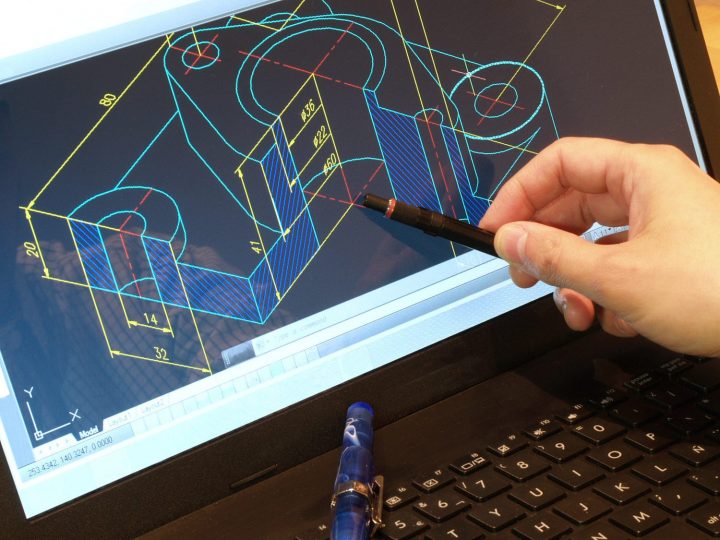

3D Modeling Software

In any 3D printing process, the first step is going to be 3D modeling. In order to be as precise as possible, all of the objects will need to be designed with 3D modeling software.

Some objects have designs that are simply too intricate for traditional manufacturing methods. This is why CAD software is so effective.

With 3D modeling, manufacturers can use printers to make objects that are extremely customized and complex.

One of the reasons why 3D printing is so revered is because of its precision capabilities. There are many industries that rely on extremely precise and detailed molded objects. Teeth aligners in the orthodontic industry are just one example of an object that is unique and intricately molded.

Slicing the Model

After a model is generated, it is time to “slice” it. 3D printers do not have the ability to understand the concept of three dimensions. This means that engineers need to make slices of the model that will be layered in order for the printer to make a complete object.

With slicing software, scans of every layer of a model are made. The printer is then told how to move in order to create that layer.

3D printers are also told where they need to fill the model. This fill will give internal columns and lattices to objects that will help to strengthen and shape them.

After the model has been digitally sliced, it will be sent to the 3D printer where it will be physically printed.

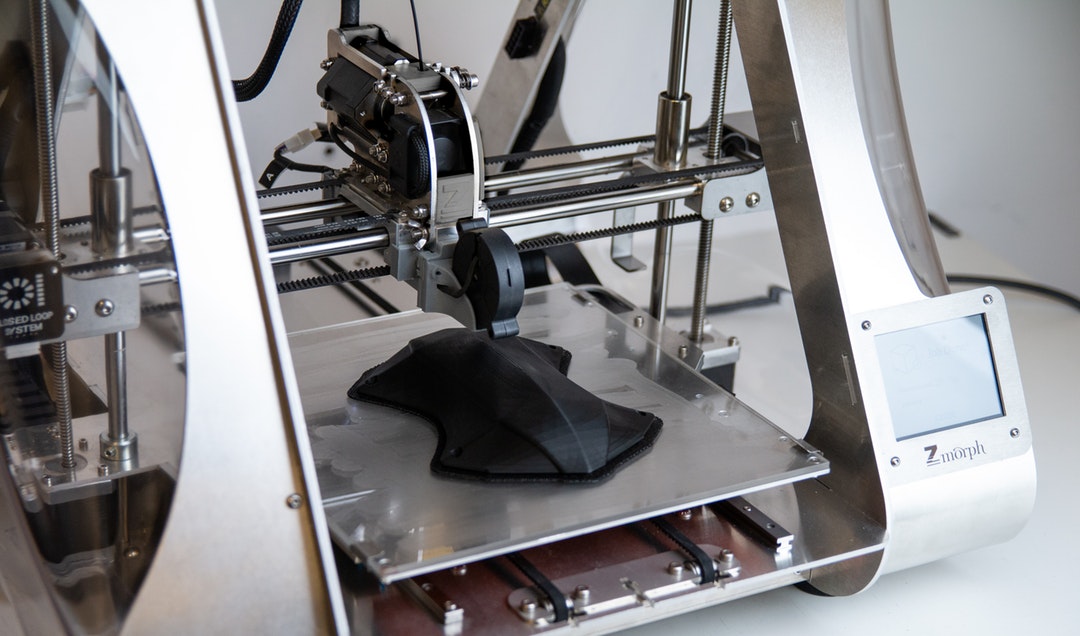

The 3D Printing Process

After the process of modeling and slicing has been completed, it is then time for the 3D printer to take over. The printer will generally act the same as a standard inkjet printer in the direct 3D printing process.

A nozzle is going to move back and forth while it dispenses a plastic-like polymer or wax. It will do this layer-by-layer. The printer will wait for each layer to dry before it adds a new layer.

Basically, it adds hundreds or thousands of 2D prints on top of one another. This is what makes a three-dimensional object.

Printers use a variety of resources in order to create the desired object.

This whole process can take a couple of hours for very simple prints, like a ball or a box. However, if you wanted to 3D print something like a house, then the whole process could end up taking several weeks.

There are also different kinds of 3D printing, depending on the scope, detail, and size of a project. One of the most popular forms of 3D printing is Fused Deposition Modeling (FDM). This is mainly used when making prototypes with plastic.

Stereolithography (SLA) Technology is a prototyping printing type that is good for making intricate objects.

The Importance of Knowing About 3D Printing

Hopefully, after reading the above article, you now have a better idea of what 3D printing is and how it works. As we can see, 3D printing offers manufacturers a wide variety of possibilities.

For many people, this means that manufacturing items will become faster, easier, and more affordable.

Are you looking to buy a 3D printer or for a 3D printing service? Make sure to contact us today and see how we can help you!